As global attention turns toward Climate Week NYC and COP30, much of the conversation centers on decarbonization and fossil fuels. However, focusing solely on energy overlooks a vital opportunity: the circular economy. The Ellen MacArthur Foundation highlights that 45% of global emissions come not from energy consumption, but from how we produce, use, and dispose of products, materials, and food—areas where circular strategies are essential.

Circularity has evolved beyond a trendy concept into a strategic approach for businesses. Demand for critical materials like lithium, cobalt, copper, and petroleum is expected to nearly quadruple by 2030, already surpassing current production capacities. The challenge extends beyond electronics and batteries, affecting all material streams, including petroleum-based plastics used in packaging, consumer goods, and industrial applications.

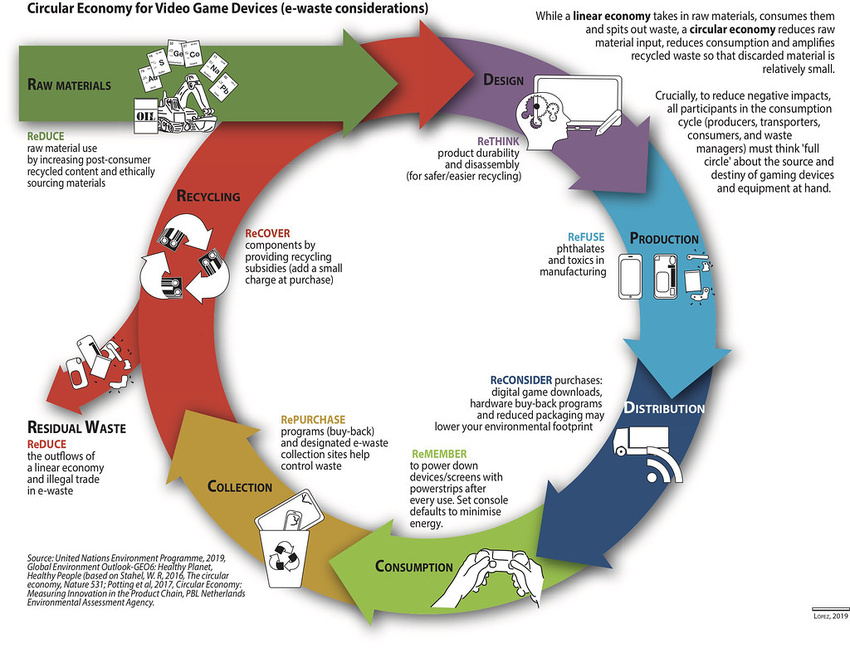

Today’s linear model—extracting oil, turning it into plastic products, using them, and discarding them—is increasingly unsustainable. The International Energy Agency (IEA) projects that by 2050, up to 20% of global oil output will be devoted to plastic production. This trajectory depletes finite resources, increases CO₂ emissions, and damages ecosystems.

Embracing reuse, repair, and remanufacturing helps companies reduce reliance on imported materials, create new revenue streams, and strengthen trust with customers. Leading firms are integrating circular strategies not as optional initiatives, but as core approaches to build resilience amid global supply disruptions. By reclaiming materials from waste streams and extending product lifecycles, companies gain predictable, controllable resource flows, improving both margins and operational stability.

Regulations are increasingly shaping this shift. Extended Producer Responsibility (EPR) programs, plastic taxes, and sustainability standards are compelling companies to rethink packaging, product design, and material management. Circular design principles and careful material selection are central to this transition. EPR initiatives reward companies for retaining value creation within local or regional economies.

Regulatory Momentum: Eco-Design, EPR, and Plastic Taxes

Governments are leveraging regulations to promote circularity. EPR schemes and plastic taxes require companies to manage the full lifecycle of their products, including post-consumer waste.

The European Union is spearheading action with the 2024 Ecodesign for Sustainable Products Regulation (ESPR), which covers packaging, material recyclability, and sustainable product design. Alongside plastic taxes in the EU and UK, these measures encourage reuse and recycling over the consumption of finite resources, pushing businesses toward circular product strategies.

In the U.S., progress is ongoing but fragmented, with state-level EPR regulations creating complexity for businesses operating across multiple regions. Globally, 185 countries are negotiating a treaty to eliminate plastic pollution by 2040, emphasizing a closed-loop approach and sustainable alternatives. Although the INC 5.2 talks in Geneva did not produce a final agreement, discussions continue with strong momentum.

Nestlé’s Global Public Affairs Lead, Jodie Roussell, emphasizes, “We are at a critical juncture where business, civil society, and governments are calling for harmonized regulations to tackle plastic pollution. An ambitious global treaty covering the full plastic lifecycle can ensure cross-border consistency, support national goals, and provide the most cost-effective path forward. Voluntary initiatives alone cannot meet these challenges, and fragmented regulations increase costs and complexity for businesses.”

Circular Design: Beyond the Product Lifecycle

Circular design maximizes resource efficiency throughout a product’s life. Businesses must plan for recyclability, durability, repair, reuse, and disassembly to recover valuable materials.

This forward-thinking approach is essential for sustainability. Companies that embed environmental impact, material recovery, and product circularity from the earliest stages of development can design for long-term resource stewardship.

Data as a Foundation for Circularity

Data is crucial to track material composition, production flows, and end-of-life outcomes. Digital Product Passports (DPPs), a key component of the ESPR, provide detailed information on a product’s materials, recyclability, carbon footprint, and potential for disassembly.

Platforms like SAP Sustainability Data Exchange allow companies to monitor carbon footprints across supply chains and identify recycled content in products, supporting more informed material decisions.

Overcoming Challenges in Scaling Circularity

Navigating the growing volume and complexity of regulations, combined with intricate supply chains, makes large-scale circularity challenging. Achieving this requires precise, real-time material tracking.

SAP Responsible Design and Production helps businesses manage this complexity. By integrating enterprise and third-party data with regulatory requirements, it automates compliance with EPR rules, calculates associated fees and taxes, and identifies opportunities to optimize materials—reducing costs and environmental impact simultaneously.

Shaping a Circular Future

The transition to a circular economy relies on strategic decisions supported by robust data. Companies adopting these principles can reduce their environmental footprint, ensure reliable access to materials, and future-proof their operations against evolving regulations and market shifts.

Circularity has evolved beyond a trendy concept into a strategic approach for businesses. Demand for critical materials like lithium, cobalt, copper, and petroleum is expected to nearly quadruple by 2030, already surpassing current production capacities. The challenge extends beyond electronics and batteries, affecting all material streams, including petroleum-based plastics used in packaging, consumer goods, and industrial applications.

Today’s linear model—extracting oil, turning it into plastic products, using them, and discarding them—is increasingly unsustainable. The International Energy Agency (IEA) projects that by 2050, up to 20% of global oil output will be devoted to plastic production. This trajectory depletes finite resources, increases CO₂ emissions, and damages ecosystems.

Embracing reuse, repair, and remanufacturing helps companies reduce reliance on imported materials, create new revenue streams, and strengthen trust with customers. Leading firms are integrating circular strategies not as optional initiatives, but as core approaches to build resilience amid global supply disruptions. By reclaiming materials from waste streams and extending product lifecycles, companies gain predictable, controllable resource flows, improving both margins and operational stability.

Regulations are increasingly shaping this shift. Extended Producer Responsibility (EPR) programs, plastic taxes, and sustainability standards are compelling companies to rethink packaging, product design, and material management. Circular design principles and careful material selection are central to this transition. EPR initiatives reward companies for retaining value creation within local or regional economies.

Regulatory Momentum: Eco-Design, EPR, and Plastic Taxes

Governments are leveraging regulations to promote circularity. EPR schemes and plastic taxes require companies to manage the full lifecycle of their products, including post-consumer waste.

The European Union is spearheading action with the 2024 Ecodesign for Sustainable Products Regulation (ESPR), which covers packaging, material recyclability, and sustainable product design. Alongside plastic taxes in the EU and UK, these measures encourage reuse and recycling over the consumption of finite resources, pushing businesses toward circular product strategies.

In the U.S., progress is ongoing but fragmented, with state-level EPR regulations creating complexity for businesses operating across multiple regions. Globally, 185 countries are negotiating a treaty to eliminate plastic pollution by 2040, emphasizing a closed-loop approach and sustainable alternatives. Although the INC 5.2 talks in Geneva did not produce a final agreement, discussions continue with strong momentum.

Nestlé’s Global Public Affairs Lead, Jodie Roussell, emphasizes, “We are at a critical juncture where business, civil society, and governments are calling for harmonized regulations to tackle plastic pollution. An ambitious global treaty covering the full plastic lifecycle can ensure cross-border consistency, support national goals, and provide the most cost-effective path forward. Voluntary initiatives alone cannot meet these challenges, and fragmented regulations increase costs and complexity for businesses.”

Circular Design: Beyond the Product Lifecycle

Circular design maximizes resource efficiency throughout a product’s life. Businesses must plan for recyclability, durability, repair, reuse, and disassembly to recover valuable materials.

This forward-thinking approach is essential for sustainability. Companies that embed environmental impact, material recovery, and product circularity from the earliest stages of development can design for long-term resource stewardship.

Data as a Foundation for Circularity

Data is crucial to track material composition, production flows, and end-of-life outcomes. Digital Product Passports (DPPs), a key component of the ESPR, provide detailed information on a product’s materials, recyclability, carbon footprint, and potential for disassembly.

Platforms like SAP Sustainability Data Exchange allow companies to monitor carbon footprints across supply chains and identify recycled content in products, supporting more informed material decisions.

Overcoming Challenges in Scaling Circularity

Navigating the growing volume and complexity of regulations, combined with intricate supply chains, makes large-scale circularity challenging. Achieving this requires precise, real-time material tracking.

SAP Responsible Design and Production helps businesses manage this complexity. By integrating enterprise and third-party data with regulatory requirements, it automates compliance with EPR rules, calculates associated fees and taxes, and identifies opportunities to optimize materials—reducing costs and environmental impact simultaneously.

Shaping a Circular Future

The transition to a circular economy relies on strategic decisions supported by robust data. Companies adopting these principles can reduce their environmental footprint, ensure reliable access to materials, and future-proof their operations against evolving regulations and market shifts.

Circular Economy Strategies: Reducing Emissions & Boosting Resource Efficiency

Circular Economy Strategies: Reducing Emissions & Boosting Resource Efficiency

Companies

Companies