Fuel without bounds: Research office in Dresden delivers first bunch of Audi e-diesel

• The decision: Pilot plant creates amazing diesel fuel

• No requirement for mineral oil: e-diesel produced using water, CO2 and green force

• Minister Wanka: "Engineered diesel utilizing CO2 is a colossal achievement"

After an authorizing period of only four months, the examination office in Dresden began creating its first groups of top notch diesel fuel a couple of days back. To exhibit its suitability for regular utilization, Federal Minister of Education and Research Prof. Dr. Johanna Wanka put the initial five liters into her official auto, an Audi A8 3.0 TDI clean diesel quattro*, this Tuesday. "This manufactured diesel, made utilizing CO2, is a colossal accomplishment for our manageability research. On the off chance that we can make across the board utilization of CO2 as a crude material, we will make a significant commitment to atmosphere insurance and the proficient utilization of assets, and put the basics of the "green economy" set up," announced Wanka.

The Dresden vitality innovation organization sunfire is Audi's task accomplice and the plant administrator. It works as indicated by the ability to fluid (PtL) standard and uses green energy to create a fluid fuel. The main crude materials required are water and carbon dioxide. The CO2 utilized is presently supplied by a biogas office. Likewise, at first a segment of the CO2 required is removed from the encompassing air by method for direct air catching, an innovation of Audi's Zurich based accomplice Climeworks.

Reiner Mangold, Head of Sustainable Product Development at Audi, sees Audi e diesel and Audi e fills when all is said in done as an essential segment that supplements electric portability: "In creating Audi e-diesel we are advancing another fuel in light of CO2 that will permit long separation versatility with practically no effect on the atmosphere. Utilizing CO2 as a crude material speaks to an opportunity for the car business in Germany, as well as to exchange the standard to different parts and nations."

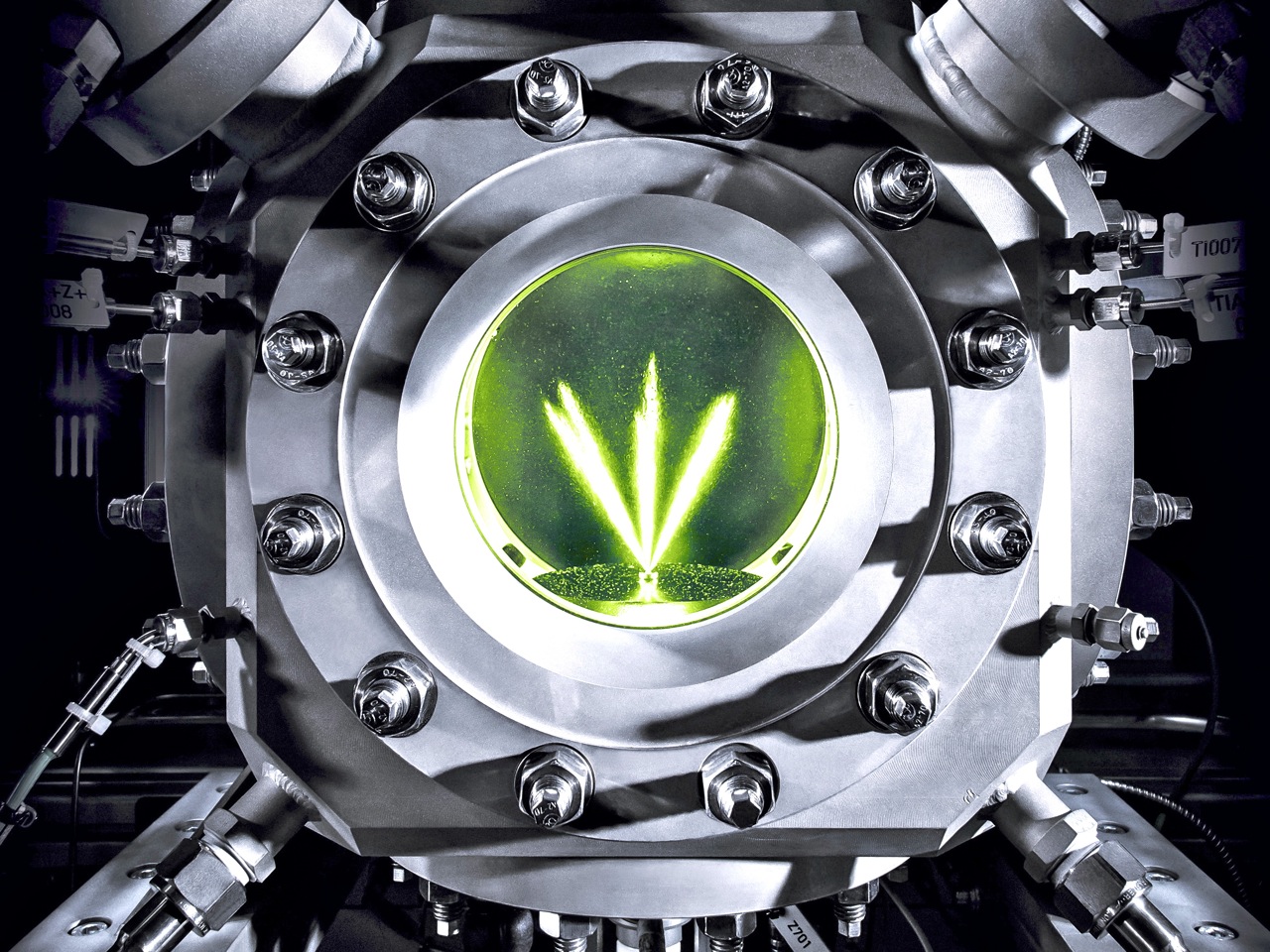

Generation of Audi e diesel includes different steps: First, water warmed up to frame steam is separated into hydrogen and oxygen by method for high-temperature electrolysis. This methodology, including a temperature in overabundance of 800 degrees Celsius, is more effective than ordinary methods in light of warmth recuperation, for instance. Another uncommon highlight of high-temperature electrolysis is that it can be utilized alertly, to balance out the lattice when generation of green force tops.

In two further steps, the hydrogen responds with the CO2 in combination reactors, again under weight and at high temperature. The response item is a fluid produced using long chain hydrocarbon mixes, known as blue unrefined. The effectiveness of the general methodology – from renewable energy to fluid hydrocarbon – is high at around 70 percent. So also to a fossil raw petroleum, blue rough can be refined to yield the finished item Audi e diesel. This manufactured fuel is free from sulfur and sweet-smelling hydrocarbons, and its high cetane number means it is promptly ignitable. As lab tests led at Audi have demonstrated to, it is suitable for admixing with fossil diesel or, tentatively, for utilization as a fuel in its own particular right.

The Federal Ministry of Education and Research is supporting the sunfire venture, which began in May 2012. Development deal with the office in Dresden Reick commenced in July 2013 and the plant was authorized on November 14, 2014. The plant is situated to deliver more than 3,000 liters (792.5 US gal) of Audi e diesel over the advancing months. Audi is sunfire's elite accomplice in the auto division.

Well beyond the association with sunfire, Audi has been dynamic in the improvement of CO2 unbiased energizes – Audi e powers – since 2009. The Audi e gas plant in Werlte, Lower Saxony, as of now delivers Audi e gas (manufactured methane) in a similar way; drivers of the Audi A3 Sportback g tron* can top off on it utilizing an extraordinary fuel card. Audi is additionally leading joint examination into the engineered production of Audi e fuel with Global Bioenergies, of France. In a further venture, Audi has united with the U.S. organization Joule, which utilizes microorganisms to deliver the manufactured energizes Audi e diesel.

Fuel consumption of the models named above:

Audi A8:

Combined fuel consumption in l/100 km: 5.9 (39.9 US mpg)**;

Combined CO2 emissions in g/km: 155 (249.4 g/mi)**

Audi A3 Sportback g-tron:

CNG consumption in kg/100 kilometers: 3.3 – 3.2 (71.3 – 73.5 US mpg)**;

Combined fuel consumption in l/100 km: 5.2 – 5.0 (45.2 – 47.0 US mpg)**;

Combined CO2 emissions in g/km (CNG): 92 – 88 (148.1 – 141.6 g/mi)**;

Combined CO2 emissions in g/km (gasoline): 120 – 115 (193.1 – 185.1 g/mi)**

**The fuel consumption and the CO2 emissions of a vehicle vary due to the choice of wheels and tires. They not only depend on the efficient utilization of the fuel by the vehicle, but are also influenced by driving behavior and other non-technical factors.

References:

http://www.geek.com/science/audi-develops-synthetic-diesel-from-co2-1621481/

https://www.audi-mediaservices.com/publish/ms/content/en/public/pressemitteilungen/2015/04/21/fuel_of_the_future.html

• The decision: Pilot plant creates amazing diesel fuel

• No requirement for mineral oil: e-diesel produced using water, CO2 and green force

• Minister Wanka: "Engineered diesel utilizing CO2 is a colossal achievement"

After an authorizing period of only four months, the examination office in Dresden began creating its first groups of top notch diesel fuel a couple of days back. To exhibit its suitability for regular utilization, Federal Minister of Education and Research Prof. Dr. Johanna Wanka put the initial five liters into her official auto, an Audi A8 3.0 TDI clean diesel quattro*, this Tuesday. "This manufactured diesel, made utilizing CO2, is a colossal accomplishment for our manageability research. On the off chance that we can make across the board utilization of CO2 as a crude material, we will make a significant commitment to atmosphere insurance and the proficient utilization of assets, and put the basics of the "green economy" set up," announced Wanka.

The Dresden vitality innovation organization sunfire is Audi's task accomplice and the plant administrator. It works as indicated by the ability to fluid (PtL) standard and uses green energy to create a fluid fuel. The main crude materials required are water and carbon dioxide. The CO2 utilized is presently supplied by a biogas office. Likewise, at first a segment of the CO2 required is removed from the encompassing air by method for direct air catching, an innovation of Audi's Zurich based accomplice Climeworks.

Reiner Mangold, Head of Sustainable Product Development at Audi, sees Audi e diesel and Audi e fills when all is said in done as an essential segment that supplements electric portability: "In creating Audi e-diesel we are advancing another fuel in light of CO2 that will permit long separation versatility with practically no effect on the atmosphere. Utilizing CO2 as a crude material speaks to an opportunity for the car business in Germany, as well as to exchange the standard to different parts and nations."

Generation of Audi e diesel includes different steps: First, water warmed up to frame steam is separated into hydrogen and oxygen by method for high-temperature electrolysis. This methodology, including a temperature in overabundance of 800 degrees Celsius, is more effective than ordinary methods in light of warmth recuperation, for instance. Another uncommon highlight of high-temperature electrolysis is that it can be utilized alertly, to balance out the lattice when generation of green force tops.

In two further steps, the hydrogen responds with the CO2 in combination reactors, again under weight and at high temperature. The response item is a fluid produced using long chain hydrocarbon mixes, known as blue unrefined. The effectiveness of the general methodology – from renewable energy to fluid hydrocarbon – is high at around 70 percent. So also to a fossil raw petroleum, blue rough can be refined to yield the finished item Audi e diesel. This manufactured fuel is free from sulfur and sweet-smelling hydrocarbons, and its high cetane number means it is promptly ignitable. As lab tests led at Audi have demonstrated to, it is suitable for admixing with fossil diesel or, tentatively, for utilization as a fuel in its own particular right.

The Federal Ministry of Education and Research is supporting the sunfire venture, which began in May 2012. Development deal with the office in Dresden Reick commenced in July 2013 and the plant was authorized on November 14, 2014. The plant is situated to deliver more than 3,000 liters (792.5 US gal) of Audi e diesel over the advancing months. Audi is sunfire's elite accomplice in the auto division.

Well beyond the association with sunfire, Audi has been dynamic in the improvement of CO2 unbiased energizes – Audi e powers – since 2009. The Audi e gas plant in Werlte, Lower Saxony, as of now delivers Audi e gas (manufactured methane) in a similar way; drivers of the Audi A3 Sportback g tron* can top off on it utilizing an extraordinary fuel card. Audi is additionally leading joint examination into the engineered production of Audi e fuel with Global Bioenergies, of France. In a further venture, Audi has united with the U.S. organization Joule, which utilizes microorganisms to deliver the manufactured energizes Audi e diesel.

Fuel consumption of the models named above:

Audi A8:

Combined fuel consumption in l/100 km: 5.9 (39.9 US mpg)**;

Combined CO2 emissions in g/km: 155 (249.4 g/mi)**

Audi A3 Sportback g-tron:

CNG consumption in kg/100 kilometers: 3.3 – 3.2 (71.3 – 73.5 US mpg)**;

Combined fuel consumption in l/100 km: 5.2 – 5.0 (45.2 – 47.0 US mpg)**;

Combined CO2 emissions in g/km (CNG): 92 – 88 (148.1 – 141.6 g/mi)**;

Combined CO2 emissions in g/km (gasoline): 120 – 115 (193.1 – 185.1 g/mi)**

**The fuel consumption and the CO2 emissions of a vehicle vary due to the choice of wheels and tires. They not only depend on the efficient utilization of the fuel by the vehicle, but are also influenced by driving behavior and other non-technical factors.

References:

http://www.geek.com/science/audi-develops-synthetic-diesel-from-co2-1621481/

https://www.audi-mediaservices.com/publish/ms/content/en/public/pressemitteilungen/2015/04/21/fuel_of_the_future.html

Audi’s Remarkable synthetic Diesel

Audi’s Remarkable synthetic Diesel

Companies

Companies