Dailycsr.com – 18 July 2018 – 3D printing technology has been a radical impact on the industrial as well as manufacturing sectors. However, the technology is also bringing in innovation in the education sectors, as educators are using it to reach out to their students.

The technology of 3D printing offers a new way of explanation to the students, while the educators are able to present different concepts in different manner. In fact, the technology has reach out to teacher across the globe, as the educators make 3D a tool for enhancing their “lesson plans”.

Following is the statement of “six different educators”, who currently use 3D printing for their classrooms. The descriptions for their activities give us a window to glance into the usage of 3D printings in the realms of education.

Dr. Timothy W. Simpson from the Penn State University said:

“We developed a 3D printed boat activity to introduce junior-level mechanical engineering students to the digital workflow associated with 3D printing. Specifically, we gave students a small 3D printed boat that held 5 pennies before it sank. Students were then tasked with developing ideas and redesigning the boat to hold more weight, implement their idea in CAD, and then adjust their design to meet certain 3D printing restrictions (e.g., 2hr build time and 5” x 5” max footprint). They had until the end of the lab to submit their new boat design, which we then 3D printed in Penn State’s MakerCommons and tested at the start of lab the following week”.

While, Denise Kopecky from Challenger Center added:

“In Challenger Center’s Earth to Mars Design Challenge lesson, high school students are tasked with designing the first Mars habitat. After learning about different needs of the habitat, students design the interior blueprint and create a model of the exterior, using 3D Printing Pens. The 3D Printing Pens exposed the students to new forms of technology and to the idea of 3D printing, which will be important in space habitation. The students at first struggle with the 3D printing pens, as they get used to building in 3D. However, they quickly adapt as they experiment with different strategies for creating their habitats and discover the best way to building strong structures. Once they gained more skills and released the potential of the 3D Printing Pens, students enjoyed being able to build creatively, changing the colors of the filament and adding in extra components to their habitats, such as antennae and solar panels”.

Furthermore, Dr. Jaunine Fouché of Milton Hersey School recounted:

“In our teacher Lauren Chiota’s tenth-grade biology class, students used 3D printing to complete an advanced design thinking laboratory exercise to learn about slime mold characteristics. They began the lab by using an online tool that generates 3D designs called TinkerCAD. They used the tool to create a detailed maze design, and then used the school’s 3D printers to print the designs and test the slime mold’s ability to move through the maze. 3D printing was a great way for students to test their hypothesis and create and evaluate maze prototypes—an important part of the design thinking process”.

Similarly, Lance Akiyama from Galileo Camps commented:

“The best part about incorporating 3D printing into our week-long programs is that there’s a lot of reiterative back-and-forth between the modeling phase, and then seeing how the model actually prints out. For example, on day 2 of the program, campers will learn about how to model designs that successfully print. They’ll be introduced to a evaluation flowchart that they’ll use to evaluate their models throughout the week. Campers will then practice being visionary by brainstorming a character to model, clarifying the details for their character and vision before they start working, which will be printed out by the end of today. Then, after learning some advanced tools in Tinkercad, campers will brainstorm and design a structure, such as a castle or moon base. What’s great for students is that it’s really easy to learn from mistakes in 3D printing because the errors are so visible, and the possible solutions are accessible by young 3D modelers! Getting a print to come out just right requires a lot of determination and reflection, but when it works, it’s so gratifying for those campers.

In the words of Daniel Sherling from MilliporeSigma:

“Inside our mobile science lab, which was created from a recycled shipping container, we leverage 3D printers within a larger experience around the “unseen world” or microscopic environment that exists all around us. Using 3D printers and small programmable robots, students are challenged to create a “nanorobot” that, if shrunken to nanoscale, could help fight cancer and other diseases. Students are “assigned” a disease, provided background information and the attributes their nanorobots must incorporate to battle their assigned disease. Students work in teams to design and build their nanorobot utilizing 3D printers and the robot pieces, then test and present their nanorobot to their classmates”.

And the Wanger Family Fab Lab from MSI Chicago informed:

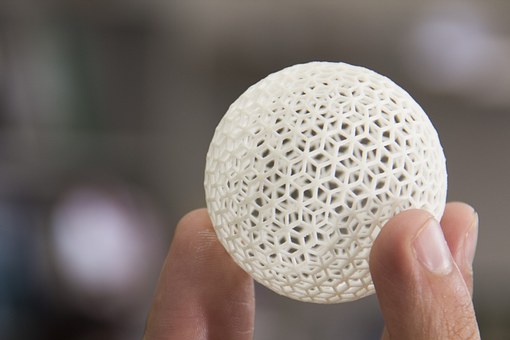

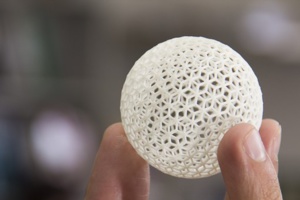

“The Museum of Science and Industry, Chicago houses the Fab Lab’s MakeCS program, which currently has over 30 different 3D Printing projects that cover the concepts of modeling with code, parametric modeling, geometric modeling and mesh modeling. Our program typically starts with mesh modeling because it is the most intuitive and easiest/fastest path to dramatic results. Using a free software called Sculptris students quickly mold a ball of “digital clay” into a little creature. They then import the model into a free “slicing” software that converts the creature into a 3D printable model. The model is then printed at the push of a button. Students, both children and adults, are shocked at how easy it is to model a complex three dimensional model and in under an hour make it real, and hold it in their hand. They also learn the extremely valuable lesson that 3D printing is a rather slow process. This results in a natural tendency to “parallel process” their design and production work”.

References:

techguided.com

The technology of 3D printing offers a new way of explanation to the students, while the educators are able to present different concepts in different manner. In fact, the technology has reach out to teacher across the globe, as the educators make 3D a tool for enhancing their “lesson plans”.

Following is the statement of “six different educators”, who currently use 3D printing for their classrooms. The descriptions for their activities give us a window to glance into the usage of 3D printings in the realms of education.

Dr. Timothy W. Simpson from the Penn State University said:

“We developed a 3D printed boat activity to introduce junior-level mechanical engineering students to the digital workflow associated with 3D printing. Specifically, we gave students a small 3D printed boat that held 5 pennies before it sank. Students were then tasked with developing ideas and redesigning the boat to hold more weight, implement their idea in CAD, and then adjust their design to meet certain 3D printing restrictions (e.g., 2hr build time and 5” x 5” max footprint). They had until the end of the lab to submit their new boat design, which we then 3D printed in Penn State’s MakerCommons and tested at the start of lab the following week”.

While, Denise Kopecky from Challenger Center added:

“In Challenger Center’s Earth to Mars Design Challenge lesson, high school students are tasked with designing the first Mars habitat. After learning about different needs of the habitat, students design the interior blueprint and create a model of the exterior, using 3D Printing Pens. The 3D Printing Pens exposed the students to new forms of technology and to the idea of 3D printing, which will be important in space habitation. The students at first struggle with the 3D printing pens, as they get used to building in 3D. However, they quickly adapt as they experiment with different strategies for creating their habitats and discover the best way to building strong structures. Once they gained more skills and released the potential of the 3D Printing Pens, students enjoyed being able to build creatively, changing the colors of the filament and adding in extra components to their habitats, such as antennae and solar panels”.

Furthermore, Dr. Jaunine Fouché of Milton Hersey School recounted:

“In our teacher Lauren Chiota’s tenth-grade biology class, students used 3D printing to complete an advanced design thinking laboratory exercise to learn about slime mold characteristics. They began the lab by using an online tool that generates 3D designs called TinkerCAD. They used the tool to create a detailed maze design, and then used the school’s 3D printers to print the designs and test the slime mold’s ability to move through the maze. 3D printing was a great way for students to test their hypothesis and create and evaluate maze prototypes—an important part of the design thinking process”.

Similarly, Lance Akiyama from Galileo Camps commented:

“The best part about incorporating 3D printing into our week-long programs is that there’s a lot of reiterative back-and-forth between the modeling phase, and then seeing how the model actually prints out. For example, on day 2 of the program, campers will learn about how to model designs that successfully print. They’ll be introduced to a evaluation flowchart that they’ll use to evaluate their models throughout the week. Campers will then practice being visionary by brainstorming a character to model, clarifying the details for their character and vision before they start working, which will be printed out by the end of today. Then, after learning some advanced tools in Tinkercad, campers will brainstorm and design a structure, such as a castle or moon base. What’s great for students is that it’s really easy to learn from mistakes in 3D printing because the errors are so visible, and the possible solutions are accessible by young 3D modelers! Getting a print to come out just right requires a lot of determination and reflection, but when it works, it’s so gratifying for those campers.

In the words of Daniel Sherling from MilliporeSigma:

“Inside our mobile science lab, which was created from a recycled shipping container, we leverage 3D printers within a larger experience around the “unseen world” or microscopic environment that exists all around us. Using 3D printers and small programmable robots, students are challenged to create a “nanorobot” that, if shrunken to nanoscale, could help fight cancer and other diseases. Students are “assigned” a disease, provided background information and the attributes their nanorobots must incorporate to battle their assigned disease. Students work in teams to design and build their nanorobot utilizing 3D printers and the robot pieces, then test and present their nanorobot to their classmates”.

And the Wanger Family Fab Lab from MSI Chicago informed:

“The Museum of Science and Industry, Chicago houses the Fab Lab’s MakeCS program, which currently has over 30 different 3D Printing projects that cover the concepts of modeling with code, parametric modeling, geometric modeling and mesh modeling. Our program typically starts with mesh modeling because it is the most intuitive and easiest/fastest path to dramatic results. Using a free software called Sculptris students quickly mold a ball of “digital clay” into a little creature. They then import the model into a free “slicing” software that converts the creature into a 3D printable model. The model is then printed at the push of a button. Students, both children and adults, are shocked at how easy it is to model a complex three dimensional model and in under an hour make it real, and hold it in their hand. They also learn the extremely valuable lesson that 3D printing is a rather slow process. This results in a natural tendency to “parallel process” their design and production work”.

References:

techguided.com

A Glance Into The Usage of 3D Printings In The Realms Of Education

A Glance Into The Usage of 3D Printings In The Realms Of Education

Companies

Companies